Familiar with the word “Bottlenecks” ??

This is a common problem of production lines which have several dependent processes and link from one to the other. The reason is simple, due to the different times required to complete the task.

The normal initial process that factories do is time study, capture the time of all processes, and use this as the reference time for Line balancing. The questions:

- How accurate is the process of collecting the information? Are we sure the operators are performing their real skills when the data was captured?

- How can we be assured if the time represents the realistic figures?

- Line balancing is not only about eliminating bottlenecks but also to minimize LOSS of unused minutes. Have we covered this area too?

Those are problems normally faced by factories, the current conventional method is just not enough…

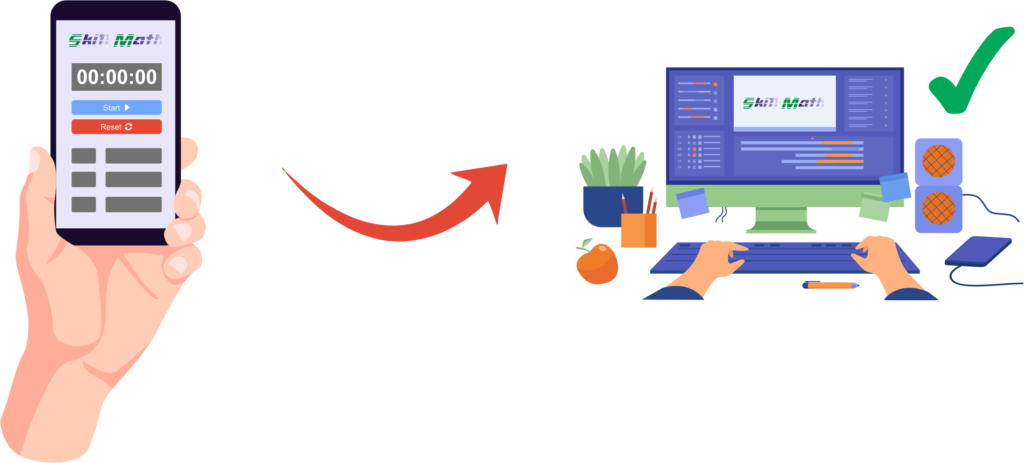

Skill-Math has a unique way of collecting time study data, just as advanced as your mobile phone or computer tablet.

The method of doing Line Balancing is by adapting the most common practice of factories ie. Defining the expected output target, Skill-Math will calculate the number of operators required for each process. On the opposite way, we can also do the line balancing based on the number of operators on each sewing line. Optimize the line balancing and get info on unused minutes for all processes.