Setting the production line based on memory…

Setting the production line based on memory…, isn’t that very risky?

Experts say that the capacity of human memory is very large, it’s just that there are many factors, both external and internal, that can trigger us to forget or misremember/confuse memories. What if this happens in our daily work…?

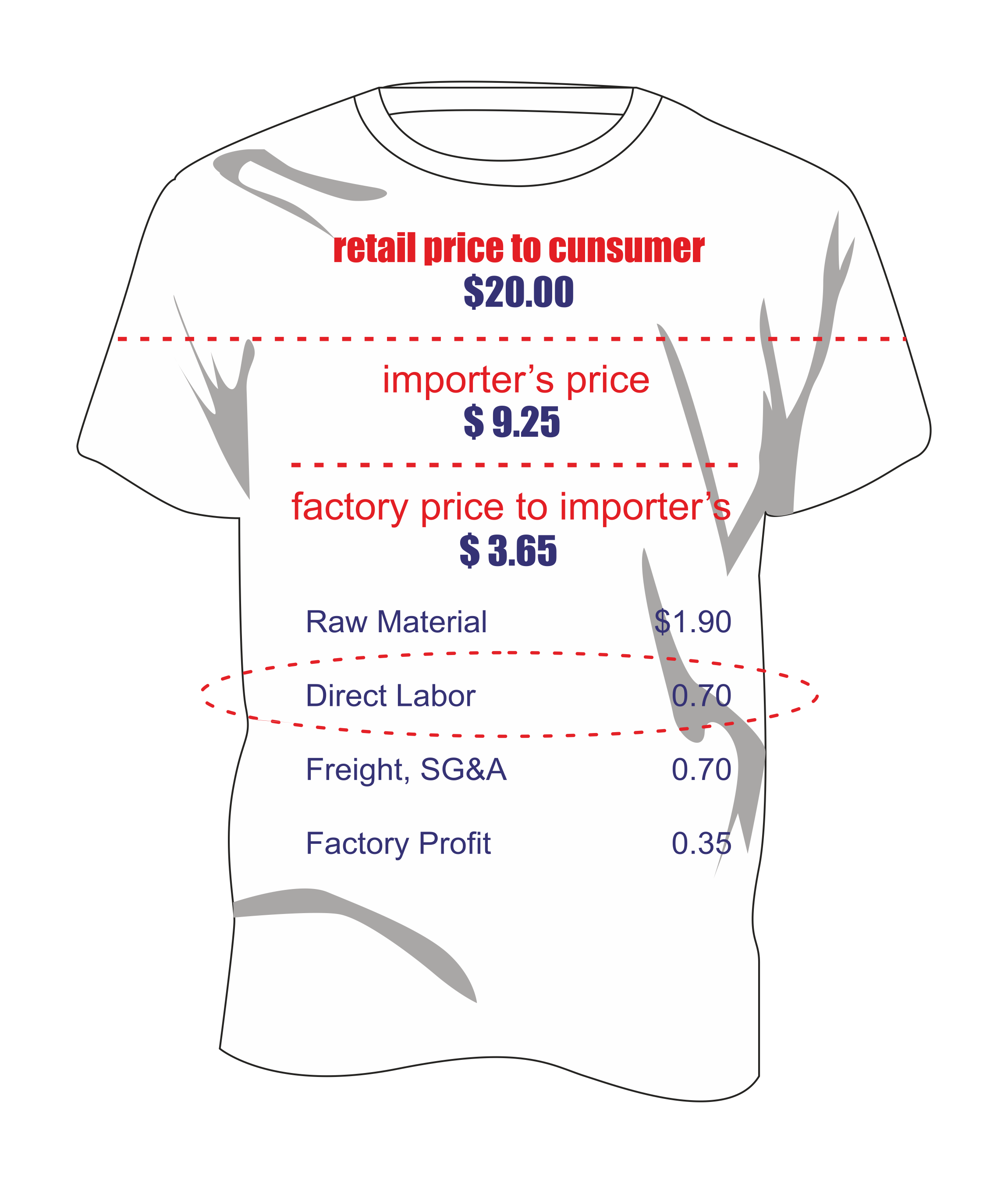

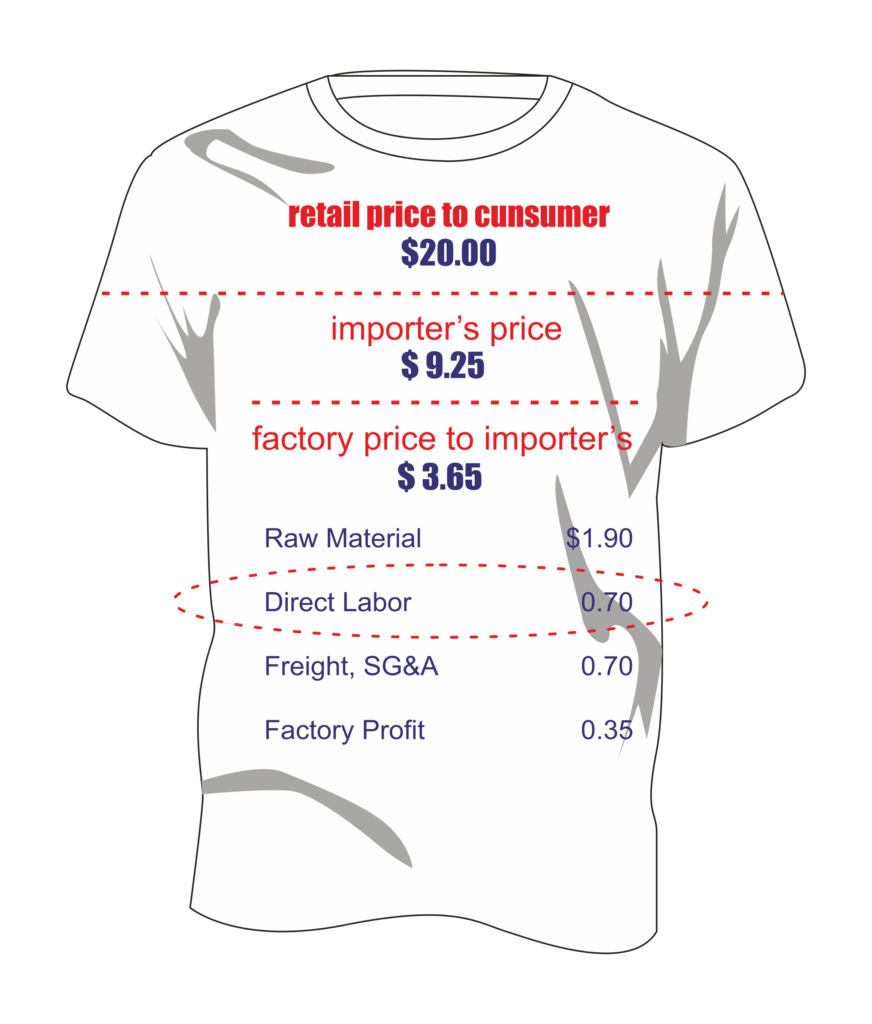

Of course, it will cause problems that can result in light to large losses for both ourselves and the company where we work.

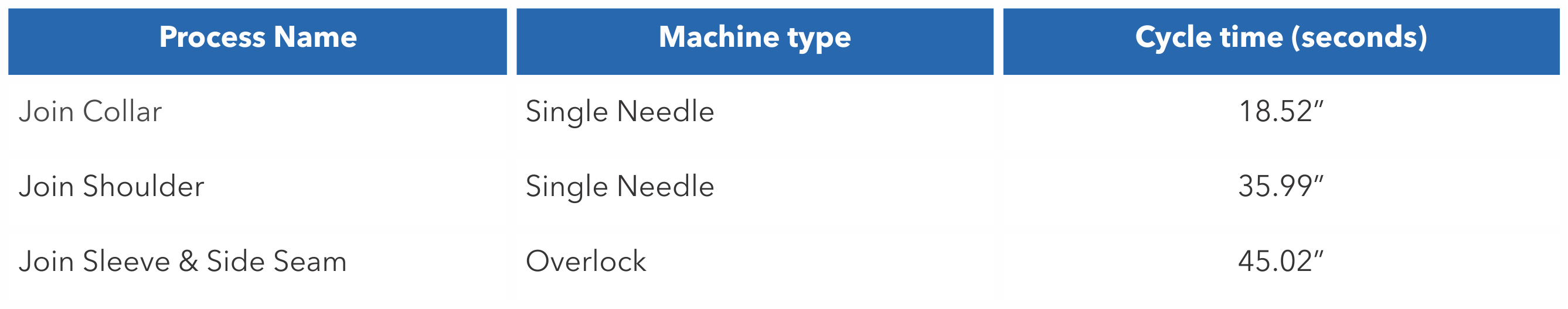

In garment manufacturing, the selection of operators to work on a process is still mostly done by relying on the memory of the operator skills that will be assigned to the process.

In more detail, the line supervisor will determine who will carry out the processes based on his/her memory of the expertise of the operators in the line he/she handles.

Where we know that there are many types of sewing processes using special techniques, different machines, and different materials just to make 1 style of garment.

So how can a supervisor remember exactly the skills of the dozens of operators he/she handles?

What would be the consequences if there was a slight misrepresentation of the operator’s skill?

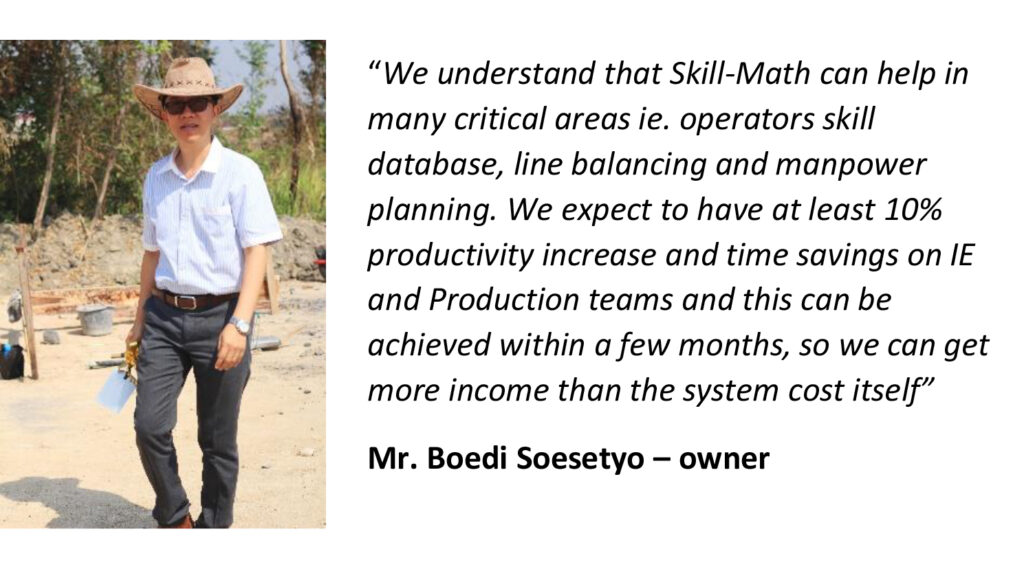

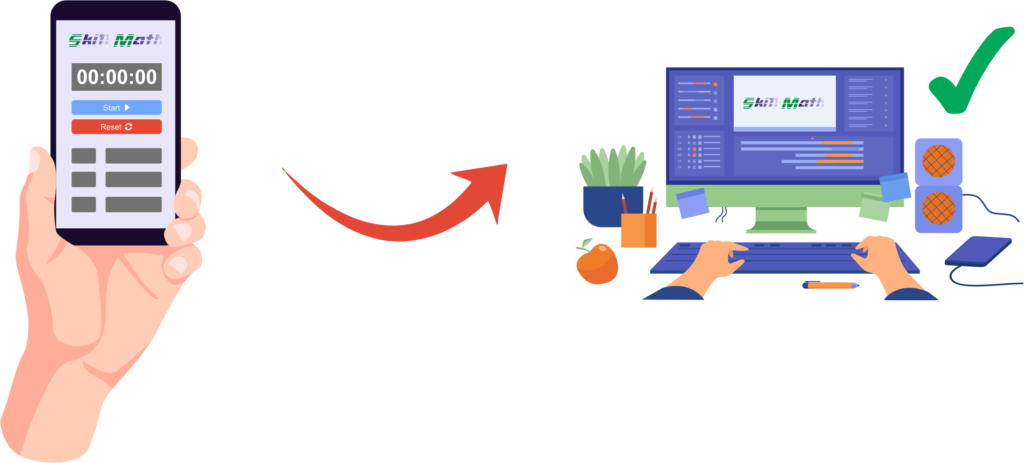

The solution to this problem is to have a system that can store complete operator data along with ratings and gradings of sewing process skills, even for all processes that can be done by the operator, easily, quickly, and accurately.

We have a solution for the system, namely Skill-Math, which will help you to overcome the problems above.