The Art of Line Balancing

Why is it an Art..?

Because it needs special skill to combine the number of operators for many different processes with various cycle times. The purpose is to get a smooth workflow, so there are several steps to be done:

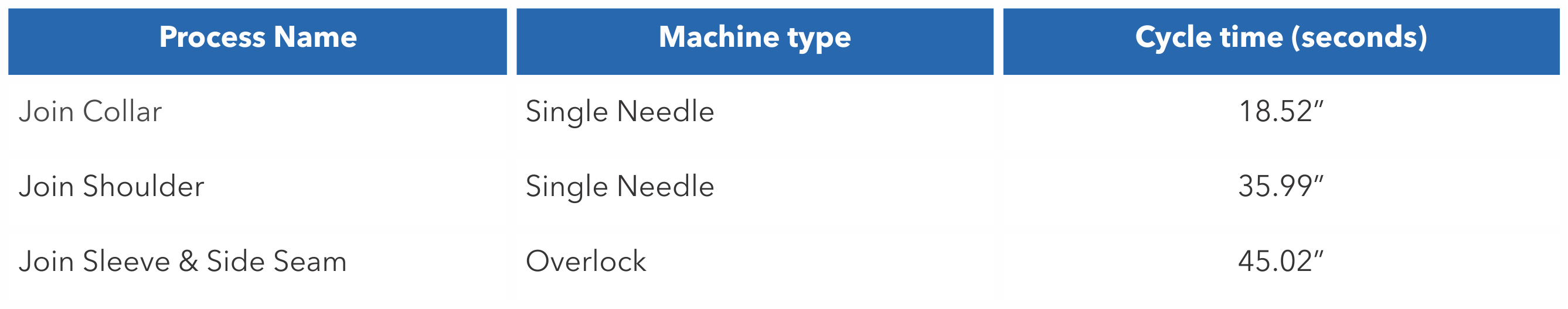

- Identify the cycle time per every single process to produce a garment

- Determine number of operator(s) for all processes for a smooth workflow

- Assign the right operator(s) for each single process

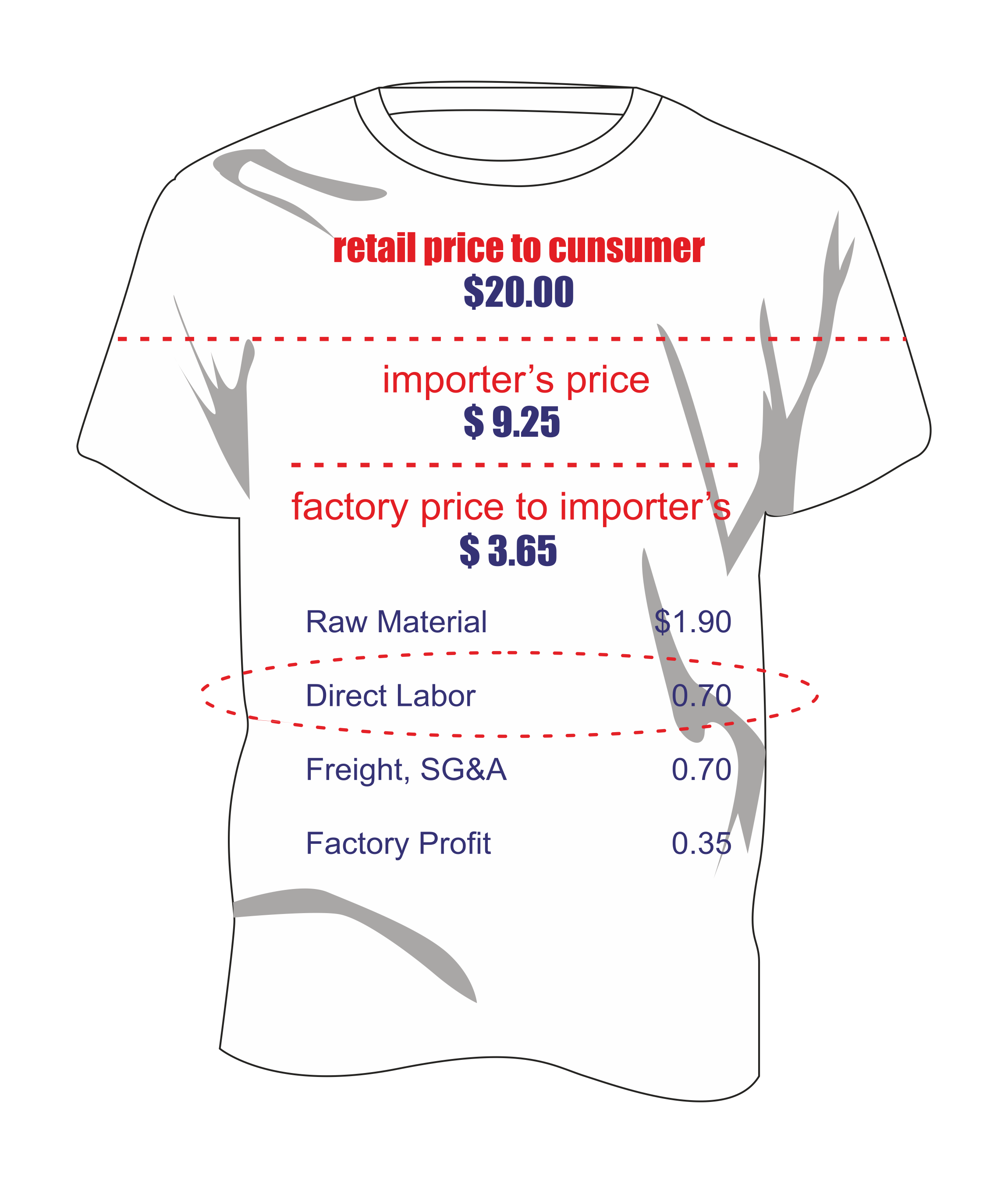

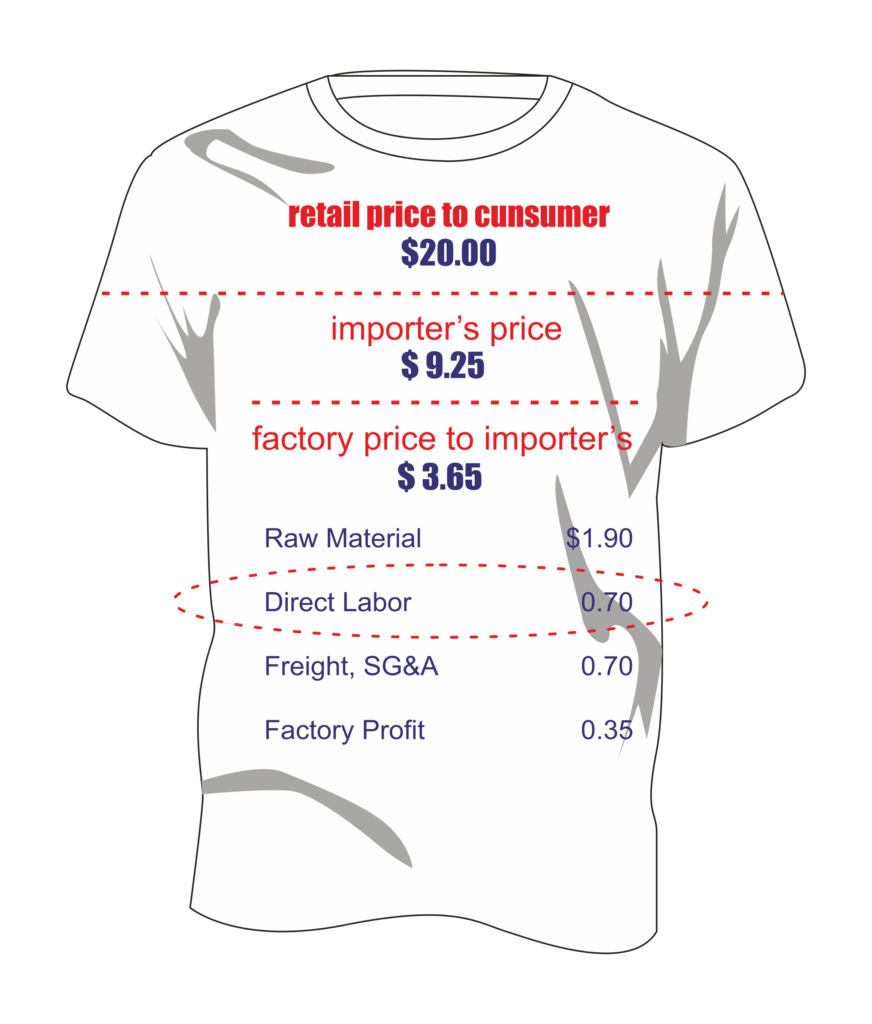

Let’s do a simple calculation as per the illustration below

If we look at the above then the number of operators should be:

We have identified the Cycle time on each process and then do the proper Line Balancing, these mean nothing if we assign the wrong operators. Supervisors/line leaders will choose the operators based on their memory, so the potential bottleneck will always happen if we do not have the skill database of our operators.

Skill-Math will help us in this area, identifying the skills of operators on each process, showing the availability of operators based on the needs at the sewing lines, and at the same time monitoring the skill-trend for further improvement.

Less bottlenecks = Higher Productivity